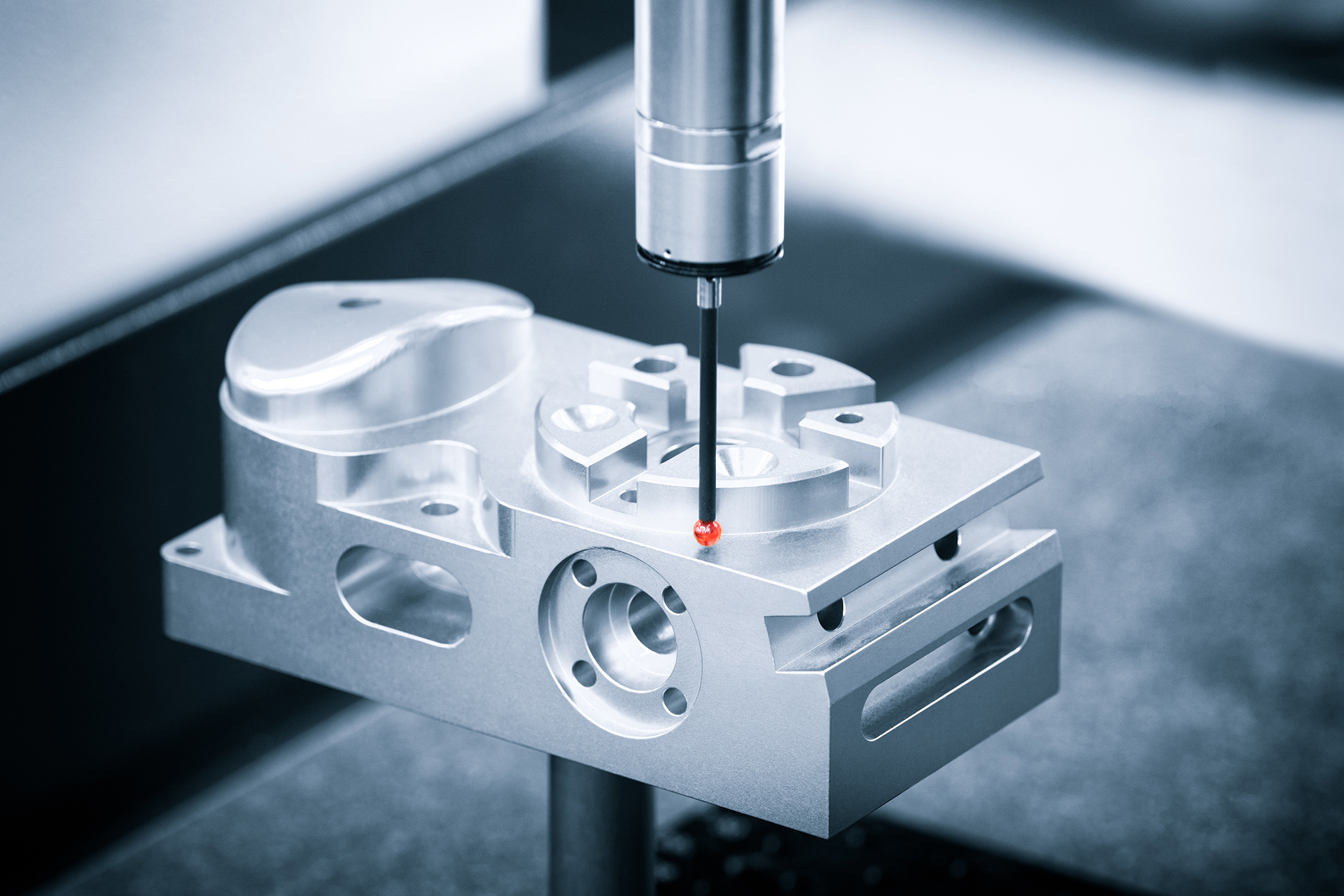

Processes & Equipment

Pacific Stainless has years of experience in metallurgy, engineering, design and CNC programming, which allows us to provide you with the very best manufacturing services regardless of your challenge.

From food service to architectural to semiconductor, let us use our over 25 years of specialized experience to build your custom project. We are here to help you suceed with ISO 9001:2015 manufacturing resources.

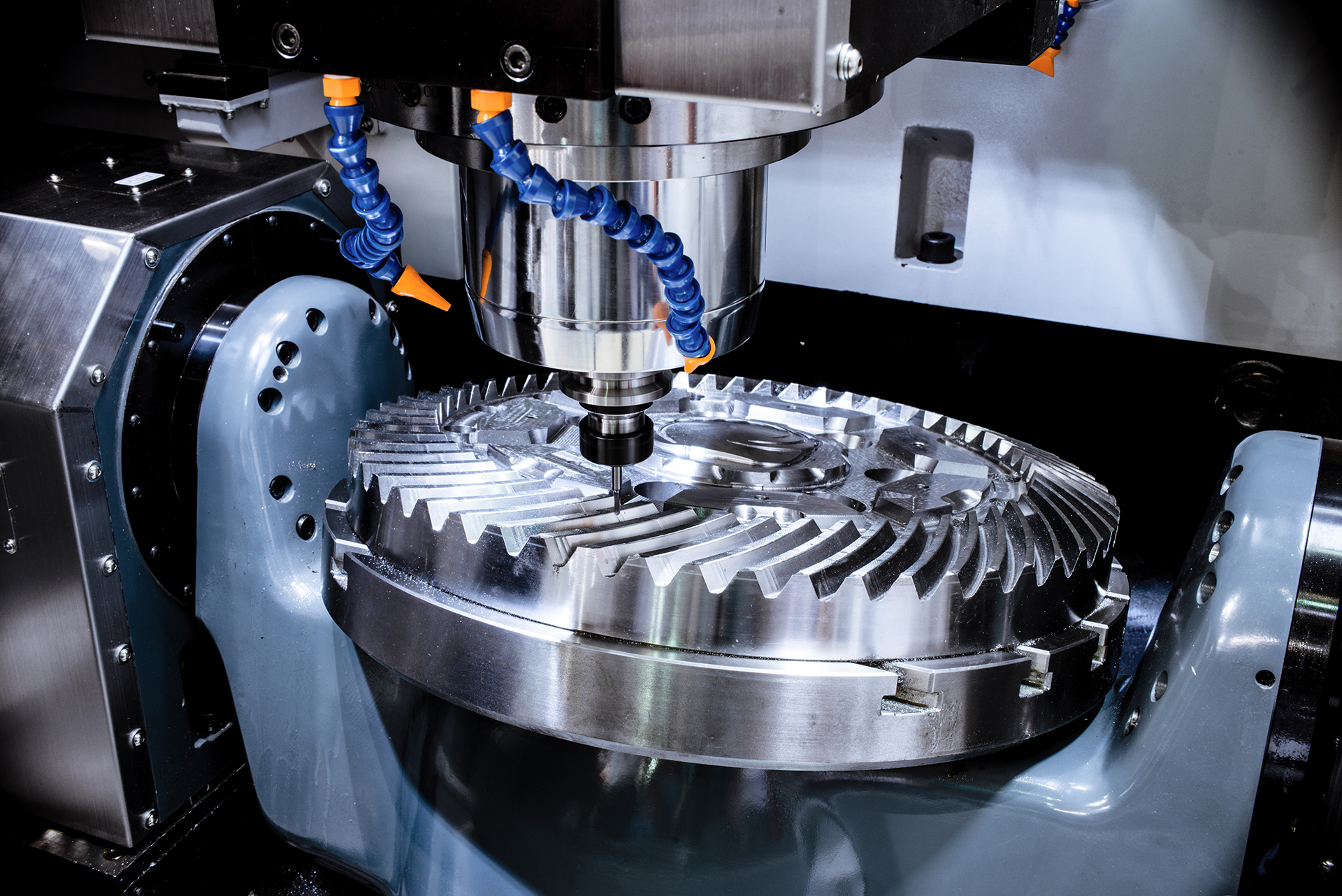

Custom Automation and Integration Solutions

Our integrated manufacturing resources and state of the art machining centers allow us to provide you with cost-effective integration services regardless of the challenge.

Our clients typically realize significant manufacturing and logistics advantages by relying on Pacific Stainless Products for their integration project needs. Our continual quality focus and ISO 9001:2015 certification ensure that your project is manufactured to the highest quality standards.

Offering over two decades of precision metal fabrication and integration experience, Pacific Stainless Products can help make your project a success from design and development through production, testing and final delivery phases.

DELIVERY

We delivers products when promised- 98% on-time over 12 months. Short lead times with a Rapid Prototype program.

CAPACITY

We have the capacity for large projects with 45 fabricators on staff.

CONTROL

We have a control of our schedule because we have a variety of internal processes, including machining and powder coating

QUALITY

Build to print without deviation. We have a very low external rejection rate. We are World Class QMS – ISO 9001:2015 Certified. Proven and Tested. We are working towards ISO 14001.

COST

In the West Coast region, our costs are lower in comparison to many regional companies, which makes us very competitive on larger projects.

Industries Served

Semiconductor

Military

Aerospace

Energy

Food Service

Architectural

Call Us Today:

(888) 618-2122